Sags & Tensions of Span Attachments

Calculation Approach

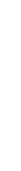

The above guidance for a starting point in calculations was necessary, but it doesn't set our starting point on the Initial Curve yet. For that you need both Stress (Tension/Area) and strain. A little more work is required. There are three sets of equations that need to be solved simultaneously in order to get this point. One set of equations is the Initial Curve itself, relating Stress (or tension) to Strain (or stretch), defined in polynomial form by the manufacturer:

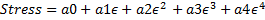

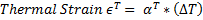

WhereThe second equation is recognition of the thermal expansion coefficient for the material:

Where

The third equation ensures that the wire or cable solution fits the physical restrictions placed upon it such as the specific span length, relative attachment heights, temperature and either a measured tension or a measured sag.

Where

S= wire or cable length between attachment points

H = horizontal tension at maximum sag point

W = load per unit length

L = effective span length

It can be shown that this formula must be true for any wire or cable that has a constant weight per unit length along the span.

It can be shown that this formula must be true for any wire or cable that has a constant weight per unit length along the span.

These three equations that define the behavior of the material and its physical restrictions are then solved, usually in an iterative manner, to land on a solution that satisfies all three. There are several methods available to software providers, some better than others.

A complication to this calculation exists when there are two types of materials in a single wire or cable. A common example is a 1/0 ACSR wire (aluminum covered steel reinforced). The three curves and thermal coefficients of both materials are all different. In these cases, the restrictions on both the core and outer materials must be satisfied at the same time. There is a manual graphical way of calculating these simultaneous equations that was developed by ALCOA many years ago. It is seldom used these days, but is still valid for any interested reader. What software tools can do for the user today is amazing compared to the manual processes of the past.

To be perfectly clear, the most common approach to getting a "starting point" is to measure or otherwise determine the appropriate tension for the wire/cable under initial wire conditions. It is also possible to make assumptions about existing wire/cables with respect to its history of creep or applied loads and use constant modulus of elasticity assumptions in the above equations. Existing wires/cables assumed to have experienced their full design loads would be the easiest to calculate, but partially stretched wires/cables are also possible to calculate. From the appropriate starting point, all other scenarios required can be calculated.