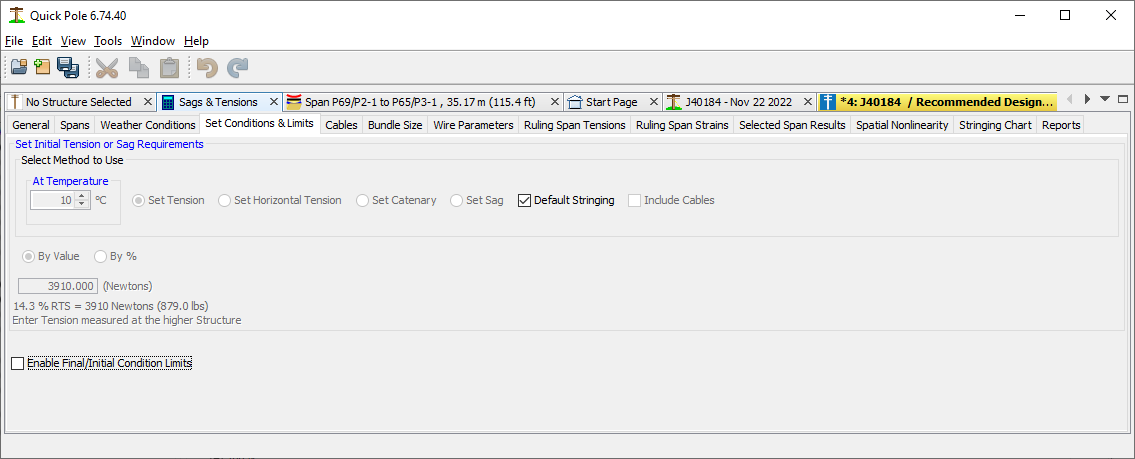

Set Conditions

On this tab is where all tension requirements are defined.

The top section called "Set Initial Tension or Sag requirements" is the same as setting an attachment's tension or sag in a project. Please see setting tension section in the Span Editor/Viewer window for more information.

The bottom section defines tension limits based on several initial or final tension scenarios.

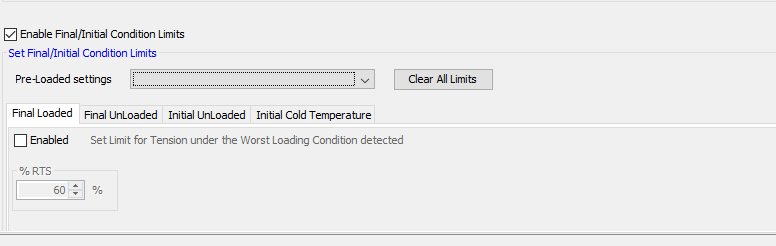

The preloaded settings choices populate these limits with some common settings suggested in national standards. Each setting can still be adjusted afterwards, but choosing a preloaded setting will erase anything you may have populated previously. The "Clear All Limits" button clears all previously entered settings and disables each of the sub-tabs.

Set Final / Initial Condition Limits

This lower section is most commonly used to help establish standard tensions for your Organization, similar to SAG-10 and PLS-CADD, by respecting certain limits. There are four sub-tabs which can be selected to put additional conditions (limits) on any tension situation. Any one of them can be used independently of the others.

If any one of these specific limits are reached when the Sags and Tensions are evaluated over any of the load conditions requested or tested, the tension will be reduced to a value where the limit will not be exceeded. Then the Sags and Tensions will be re-evaluated for all of the load conditions requested. You can use this functionality to ensure that certain limits are never exceeded, which may include:

- Maximum Tension in attachment to limit possible permanent stretch and increased sag.

- Initial/Final Tensions in average day or cold temperature conditions to help prevent aeolian vibrations

- The lowest temperature to evaluate Sag and Tension results

Initial / Final Definition

Initial Conditions represents a time very shortly after installing the attachment. It is recognized that any wire or self supporting cable will undergo certain changes once it is installed. The first one comes from the fact (and assumption) that the cable/wire was initially on a reel before it was placed and strung between poles or other structures. When the wire/cable is placed under some tension between structures, the wire/cable will undergo some mechanical setting within itself, which will lessen the tension and increase the sag somewhat. Most references suggest that this initial effect is largely dissipated within the first hour after installation. Many installation practices of Organizations recognize this effect and call for re-tensioning shortly after the initial installation. When manufacturers provide wire parameters for customers to use with their wires/cables, the ASTM testing method used has already removed the effect of this initial mechanical setting of the wire/cable. This settling relates to very small movements of the various strands of wire or other support material within the wire/cable. It has nothing to do with how the wire/cable actually behaves with respect to load, and it is small, so it is removed from wire/cable parameters by the ASTM testing methodology.

All Initial Conditions therefore refer to the wire/cable being installed and re-tensioned after one hour or the next day.

Over the lifetime of the wire/cable, it could be subjected to extreme loads or to average day tensions over a long period of time. Both situations will cause some permanent stretch to occur. Wire/Cable parameters contain information to help predict its behavior under both of these situations. Storm and other extreme conditions have a probability of occurrence, but not an absolute certainty. For that reason the standard Industry response is to evaluate the wire/cable's behavior under load conditions (called Final Load) and under average day tensions causing slow stretching activity (Final Creep). Both situations need to be computed and the worst of these conditions and the Initial conditions are required for Sag and Tension purposes.

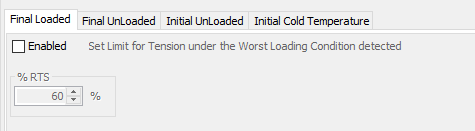

Final Loaded

This sub-tab, if enabled via the Checkbox, places an absolute upper tension limit on the attachment under any condition.

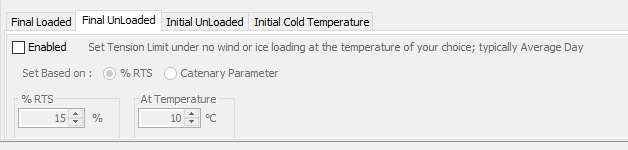

Final UnLoaded

This sub-tab, if enabled by the Checkbox, places an upper limit to the Final Tension under a specific temperature. This tension can be defined by either a percentage of UTS or with a Catenary value.

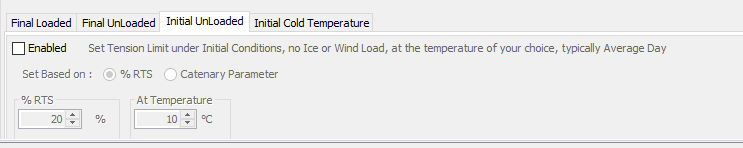

Initial Unloaded

This sub-tab is very similar to the Final Unloaded sub-tab, except that it tests against Initial Tension values. This sub-tab, if enabled by the Checkbox, places an upper limit to the Initial Tension under a specific temperature. This tension can be defined by either a percentage of UTS or with a Catenary value.

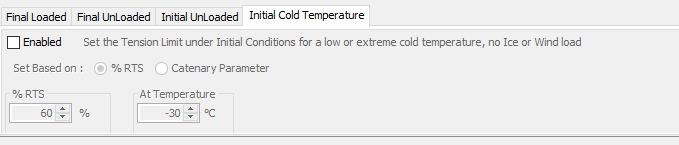

Initial Cold Temperature

This sub-tab, if enabled by the Checkbox, places an upper limit to the Initial Tension under a specific low temperature and no Wind or Ice. This tension can be defined by either a percentage of UTS or with a Catenary value.